Belt Press Sludge Dewatering

The belt filter press is used as supporting equipment for sewage treatment. It can filter and dewater the suspended solids and sediments after air flotation treatment and the sludge produced in each biochemical section of the sewage treatment into mud cakes to prevent and...

Send InquiryIntroduction

The belt filter press is used as supporting equipment for sewage treatment. It can filter and dewater the suspended solids and sediments after air flotation treatment and the sludge produced in each biochemical section of the sewage treatment into mud cakes to prevent and control secondary pollution. The purpose is a good solid-liquid separation equipment.

The upper and lower tensioned filter belts carry the sludge layer, passing through a series of regularly arranged rollers in an S-shape, and relying on the tension of the filter belt to form the squeezing and shearing force on the sludge layer. The capillary water is squeezed out to achieve sludge dehydration.

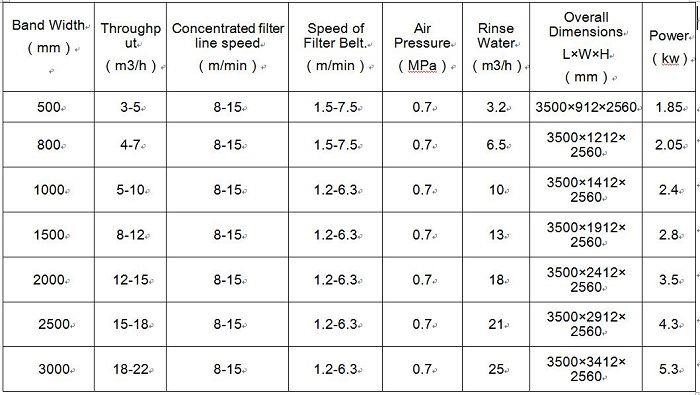

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. Frame: The belt filter press frame is mainly used to support and fix the press roller system and other components.

2. Pressing roller system: It consists of rollers with diameters arranged in order from large to small. The sludge is held by the upper and lower filter belts and passes through the press rollers in sequence, forming a pressure gradient from small to large under the tension of the filter belt, so that the pressing force of the sludge during the dewatering process is continuously increased, and Water is gradually removed.

3. Gravity zone dewatering device: It is mainly composed of gravity zone bracket and hopper. The flocculated material removes a large amount of water in the gravity area, and the fluidity becomes poor, which creates conditions for subsequent extrusion dehydration.

4. Wedge-shaped zone dewatering device: The wedge-shaped zone formed by the upper and lower filter belts exerts a pressing force on the clamped material and performs pre-pressure dewatering to meet the requirements for the liquid content and fluidity of the material in the squeeze dewatering section.

5. Filter belt: It is the main component of a belt filter press. The solid and liquid phases of the sludge are separated above and below. The lower filter belt is the filter medium. It is bypassed under the tension of the upper and lower filter belts. Press the roller to obtain the pressing force required to remove the material moisture.

6. Filter belt adjusting device: It consists of executive components: air cylinder, adjusting roller signal back pressure, and electrical system. Its role is to adjust the deviation of the filter belt caused by uneven belt tension, roller installation error, uneven feeding and other reasons, thereby ensuring the continuity and stability of the belt filter press.

7. Filter belt cleaning device: It consists of a sprayer, a cleaning water contact box and a cleaning cover. When the filter belt travels, it continuously passes through the cleaning device and is impacted by the pressure water sprayed from the sprayer. The material remaining on the filter belt is detached from the filter belt under the action of the pressure water, so that the filter belt is regenerated for the next dehydration process. ready.

8. Filter belt tensioning device: It consists of a tension cylinder, a tension roller and a synchronization mechanism. Its role is to tension the filter belt and provide the necessary tension conditions for the production of press dehydration. The adjustment of the tension can be adjusted by adjusting The pressure in the tensioning cylinder of the pneumatic system is used to achieve this.

9. Unloading device: It consists of scraper plate, knife holder, unloading roller, etc. Its function is to peel the dehydrated filter cake and filter belt to achieve the purpose of discharging.

10. Transmission device: It is composed of motor, reducer, gear transmission mechanism, etc. It is the source of power for filter belt running, and can adjust the speed of reducer to meet the requirements of different belt speeds in the process.

11. Pneumatic system: This system is mainly composed of power source (gas storage tank, motor, air pump, etc.), executive components (cylinder), and pneumatic control components (including pressure relay, pressure flow and directional control valve). The air pressure control element controls the air pressure, flow and direction to ensure that the air pressure actuator has a certain thrust and speed, and works normally according to a predetermined procedure. It is the source of power to complete the tensioning and adjustment of the filter belt

Hot Tags: belt press sludge dewatering, China, suppliers, manufacturers, factory, customized, price, OEM