Disc Rotary Fiber Bags

The fiber rotary disk filter overcomes many shortcomings such as small dirt holding capacity of traditional filtering products, easy to be blocked by dirt, filtering part needs to be disassembled and cleaned, and the state of the filter cannot be monitored.

Send InquiryDisc rotary fiber bags Introduction

It has the function of filtering raw water and automatically cleaning and draining the filter element, And the system provides uninterrupted water supply during cleaning and drainage, can monitor the working status of the filter, and the degree of automation is very high.

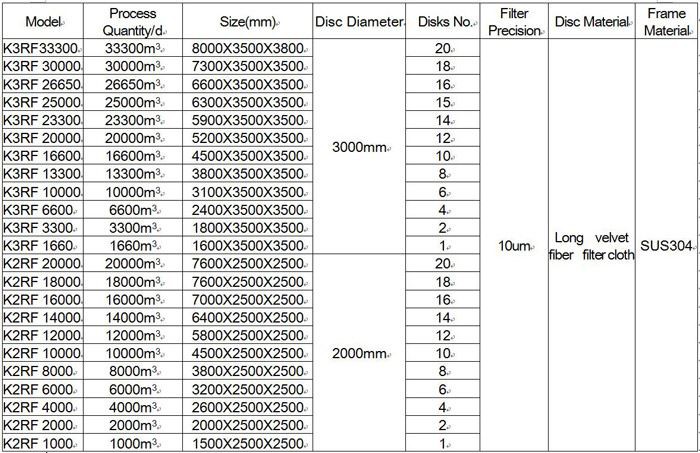

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. The fiber rotary filter has high filtration accuracy and stable effluent quality.

2. Through its own search and strain function, it realizes automatic backwashing, which can cope with unstable water quality fluctuations without manual intervention.

3. The fiber turntable filter control system is responsive, running, and has the dual setting function of pressure difference and time. It can flexibly adjust the backwash pressure difference or time setting value according to different water sources and filtration accuracy.

4. High cleaning efficiency, the filter can be completely restored to its original state, so it can be used for life without replacement.

5. Backwashing of water filtration equipment without interrupting normal water production, continuous operation, stable and reliable.

6. The backwashing time is short, the water consumption of backwashing is only 0.001 ~ 0.003% of the normal water production, saving water, electricity and energy

7. The structure design of the fiber turntable filter is compact and reasonable, the floor space is small, and the installation and movement are flexible and convenient.

8. The equipment has few wearing parts, no consumables, low operation and maintenance costs, and simple operation and management.

9. The fiber rotary filter has a wide range of applications, and can be adapted to different raw water quality and water requirements.

Working principle

The fiber rotary filter device is an electric control, an automatic valve, and a filter without special personnel management. There is no backwash system and water tower outside the body. When the suspended matter in the upper layer of the filter material rises, the flow rate of the filtered water gradually decreases, the water level in the body gradually rises, reaches the set height (negative pressure), and forms a siphon. After a few minutes, the water flow will quickly change direction and join the high water tank in the body At the same time, the water is quickly washed from the bottom upwards. When the water in the high-level water tank drops to the lowest position, the air intake in the bucket is destroyed and the siphon stops, and the water inlet quickly returns to the original water inlet direction. The device has no problem of backward migration, has high water-saving, power-saving and labor-saving characteristics, and can be matched with automatic engineering.

1. The electric control system adopts the modern programmable controller PLC as the core of the program control system. Automatically control the backwashing of filter cloth and the discharge of sludge. The core components of the system's electric control are S7200 series programming controllers and touch screens produced by the German Siemens company. The main components are Schneider products. They have reliable quality, excellent performance, strong adaptability to the environment, and good anti-interference performance. Ideal control system.

2. The system is provided with two modes: manual and automatic: in automatic mode, the operator adjusts the backwash interval as required, and the equipment can work according to the program preset by the PLC (controlled by time and level); manual mode It is only used during equipment commissioning or maintenance to realize manual control of the motors of valves, pumps and filter discs, and can operate a corresponding key to complete the backwashing function before cleaning or the pool cleaning function or the antifreeze function at shutdown.

3, S7200 can be equipped with Ethernet interface or DP interface communication interface module according to user requirements, can achieve data transmission with the plant master station.

4. Manual and automatic mode selection, parameter setting, status indication, and key operation are all completed on the touch screen; enter the corresponding interface from the initial interface, click the corresponding button to complete the corresponding operation function.

5. The touch screen system has a fault alarm prompt function; it detects the opening and closing of the valve in place, and detects the overcurrent and overload of the pump and filter disc motor. When there is a fault, the touch screen displays fault information and generates an audible and visual alarm.

Hot Tags: disc rotary fiber bags, China, suppliers, manufacturers, factory, customized, price, OEM

Previous

Rotary Disc Fibers