Jet Aerator Systems For Wastewater

The core of jet aeration system - jet aerator - is made of 316L stainless steel. Key components such as jet nozzle are patented technology. We implement comprehensive quality control in all production links from design to start, so as to ensure to provide customers with...

Send InquiryIntroduction

The core of jet aeration system - jet aerator - is made of 316L stainless steel. Key components such as jet nozzle are patented technology. We implement comprehensive quality control in all production links from design to start, so as to ensure to provide customers with products with long service life and good quality.

Jet aeration system can be widely used in the fields of pulp and paper making, chemical industry, medicine, petrochemical industry and food processing. It can also be used in municipal sewage treatment and sludge aerobic digestion. The practice shows that jet aeration system has significant advantages in reducing the cost of biochemical treatment.

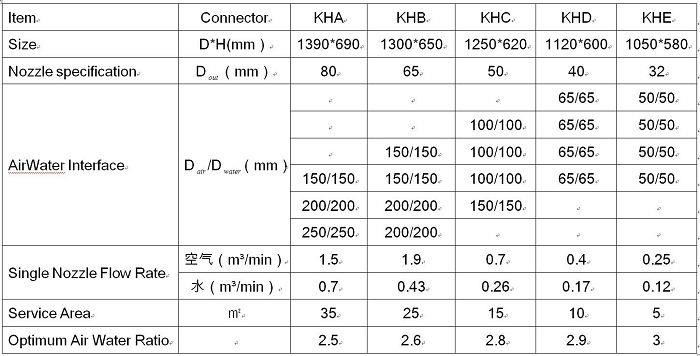

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001.

Price: Negotiable

Material: SUS304/PE

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Application

The Jet Aerators is used for mixing the pool, the fast mixing pool, the glue plume, the neutralization pool, the chemical oxidation pool, the disinfection pool, the sludge storage tank, the denitrogenation pool, the chemical reaction pool, the gas extraction system and the heat exchange system.

Equipment characteristics

1. Oxygen transfer rate

In addition to the high efficiency of oxygen transfer due to the diffusion of small air bubbles in the liquid, the turbulence generated by jet aerator makes the gas-liquid contact surface constantly updated, which is more conducive to oxygen transfer. A parameter is the ratio of oxygen transfer coefficient in sewage to that in clean water. Compared with most other microporous diffusion theories, jet aeration system has a larger a value because of its gas-liquid contact surface updating constantly.

2. Process applicability

Oxygen charging and mixing of jet aerator can be controlled separately. The operator can adjust the air volume according to the demand of dissolved oxygen, and the mixing is realized by circulating water. Combined with manual control and do instrument automatic control, energy consumption can be reduced at low load. It is very suitable for the biochemical treatment system (such as SBR) with anaerobic / aerobic alternative circulation to maintain the mixing state when the gas supply is stopped.

3. Sufficient mixing

In addition to the vertical mixing energy generated by bubble rising, circulating water also generates energy in the horizontal direction. Unlike microporous aeration system, MTS jet aeration system can be fully mixed without covering the whole tank bottom, which can save installation time and cost.

4. Reduce waste gas and water mist, and easy to control the foam wiping

With the increasingly strict atmospheric environmental quality standards, we began to pay attention to the generation of waste gas and water mist in the aeration process of sewage treatment. Due to the high oxygen utilization rate and less waste gas produced by jet aerator, only a little investment and operation cost are needed to collect and treat the waste gas. The jet aerator is a submerged design, which will not produce water mist and a large number of foam wipes like the surface aeration equipment (surface aerator, rotary brush).

5. Convenient maintenance

Jet aeration system adopts common auxiliary equipment, such as centrifugal pump, centrifugal fan or Roots fan. All rotating parts are set outside the pool, which is very convenient for maintenance. The high velocity liquid and gas in the jet aerator can avoid blocking, and the jet aerator can also be equipped with its own back flushing system.

6. Flushing device

The fluidizer can be equipped with flushing device, which can reduce maintenance cost and do not need to empty the pool. Flushing can clear the clogged aerator nozzle. Its working principle is similar to that of air lift pump. This classic flushing method only needs 5 minutes and one operator to complete. Flushing can be controlled automatically and remotely as required. Main advantages of jet aeration system (example: wastewater of a chemical plant, actual oxygen demand AOR = 1000kgo2 / h, water depth 6m)

Hot Tags: jet aerator systems for wastewater, China, suppliers, manufacturers, factory, customized, price, OEM