Reverse Osmisis Deionisation Equipment

Reverse osmosis water treatment equipment is widely used. Most water treatment equipment will use reverse osmosis.

Send InquiryReverse osmisis deionisation equipment Introduction

Reverse osmosis water treatment equipment is widely used. Most water treatment equipment will use reverse osmosis. Reverse osmosis includes single-stage reverse osmosis equipment and double-stage reverse osmosis equipment. There are two reverse osmosis systems in the two-stage reverse osmosis equipment. The role of the reverse osmosis system is to remove impurities and organic matter in the water.

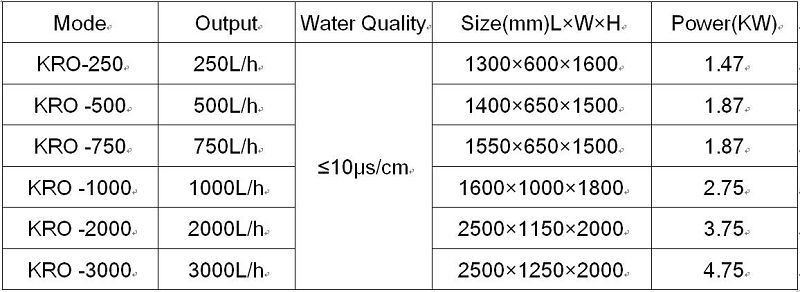

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. Online cleaning Online cleaning refers to the overall cleaning of the reverse osmosis device. The membrane element does not need to take out the pressure vessel, and is usually designed and used in larger systems. This cleaning method is simple and convenient to operate, and has a short time, but it is easy to cause cleaning failure and the effect is not ideal. This method can be used when the reverse osmosis device has less pollution.

2. Offline cleaning Offline cleaning means that the membrane elements are removed from the reverse osmosis pressure vessel and installed in special cleaning equipment for cleaning. Usually, the number of cleanings does not exceed 6 at the beginning. This cleaning method is simple and convenient to operate, and the cleaning effect is very good. However, when there are many membrane elements, the cleaning time is longer. This method can be used when the reverse osmosis pollution is serious or the online cleaning effect is poor.

Taking the cleaning agent method as the cleaning method of reverse osmosis equipment in the pure water process, according to the selected cleaning agent formula, the cleaning liquid is prepared in the cleaning water tank, and the pump is used to circulate the cleaning liquid and mix it up for use. Close the inlet water valve and discharge valve on the reverse osmosis device, and open the chemical cleaning inlet and outlet valves on the reverse osmosis device to form a circulating cleaning system. After connecting the cleaning pipeline, turn on the power switch of the cleaning pump and clean it for 1-2 hours according to the specified flow rate, pressure and temperature. The initial cleaning fluid is discharged into the trench to ensure the concentration of the cleaning fluid.

After the cleaning is completed, the residual liquid in the cleaning water tank is drained, and the water that meets the water inlet index of the reverse osmosis device is injected to rinse under the same conditions of cleaning. Or use the raw water booster pump to flush similar low-pressure flushing conditions. After the flushing of each section is completed, low-pressure flushing and high-pressure running are carried out according to the prescribed operation mode. The primary water is discharged into the ditch, and the product water tank is entered after the discharge index is qualified. After cleaning, the chemical cleaning device must be rinsed off, remember to put the cleaning filter, cleaning water pump and other equipment under acid or alkali conditions.

The debugging of reverse osmosis equipment should pay attention to: remember to close the water valve and open the high-pressure pump, which will cause great damage, so when debugging, you must pay attention to whether the pipeline is in the same state to start the pump.

Reverse osmosis technology is an advanced and energy-saving membrane separation technology. The principle is that under the effect of higher than the osmotic pressure of the solution, these substances and moisture are separated according to the fact that other substances cannot penetrate the semi-permeable membrane. Because the membrane pore size of the reverse osmosis membrane is very small (about 10A), it can effectively remove dissolved salts, colloids, microorganisms, organic matter, etc. in water (removal rate is as high as 97-98%). The system has the advantages of good water quality, low energy consumption, no pollution, simple process and easy operation.

Reverse osmosis technology is usually used for freshwater in seawater and brackish water; water softening treatment; wastewater treatment and purification, concentration, separation of food, pharmaceutical industry, chemical industry, etc. In addition, the reverse osmosis technology used in the pre-desalination treatment has also achieved good results, which can reduce the load of ion exchange resin by more than 90%, and the amount of regenerant of the resin can also be reduced by 90%. Therefore, not only cost savings, but also environmental protection. Reverse osmosis technology can also be used to remove particles, organic substances, and colloids in water, which has a good effect on reducing the pollution of ion exchange resins and prolonging the service life.

Reverse osmosis is a widely used desalination technology in the preparation of high-purity water. Its separation objects are organic substances with a range of ions and molecular weights of several hundred in the solution.) And electrodialysis (ED) technologies are both membrane separation technologies.

Quality Assurance

1.Strict contract auditing invloved all departments to assure the feasibility of each order.

2.Process design and validation before bulk production.

3.Strictly control on all raw and auxiliary materials, All raw materials reach the world advanced level.

4.On-site inspection to all processes, inspection record keep traceable for 3 years.

5.All inspectors are skilled with international certificates.

6.Qualified WPS and professional welders guarantee welding quality.

7.100% inspection of finished sprouts before shipment.

8.Advanced and complete testing and inspection equipment: NDT, metal Microscope, impact tester, hardness tester...

Hot Tags: reverse osmisis deionisation equipment, China, suppliers, manufacturers, factory, customized, price, OEM