Retrofitting Traveling Bridge Filters

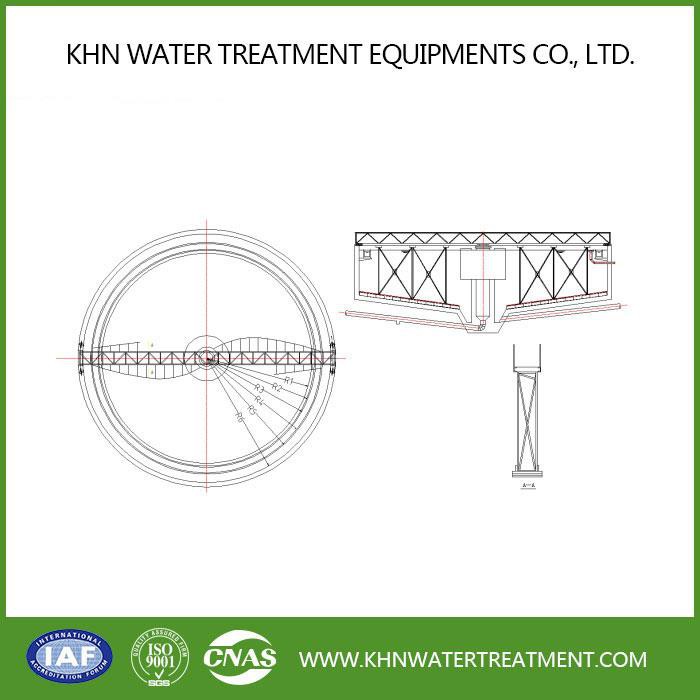

The mud scraper is mainly composed of working bridge, driving mechanism, center support, scraper arm, steady flow cylinder, scum scraper, etc. Driven by the driving mechanism, the scraping arm rotates around the central axis of the pool.

Send InquiryIntroduction

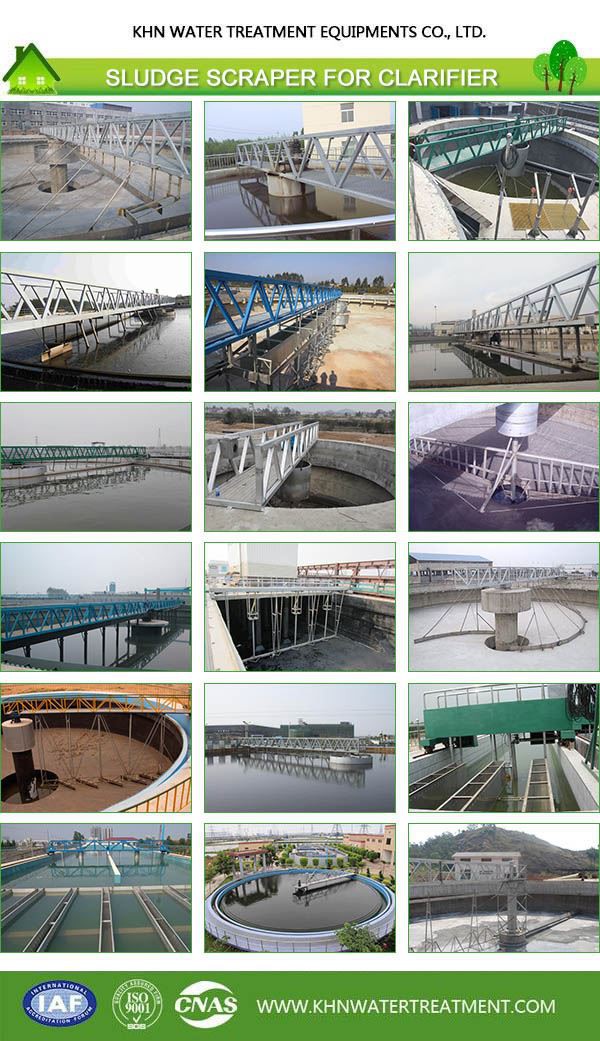

The mud scraper is mainly composed of working bridge, driving mechanism, center support, scraper arm, steady flow cylinder, scum scraper, etc. Driven by the driving mechanism, the scraping arm rotates around the central axis of the pool. A group of scraping plates installed on the scraping arm are rotating with the scraping arm, scraping the sludge settled at the bottom of the pool to the central sludge collecting pool of the pool. Meanwhile, the scum on the liquid surface is concentrated in the shrinking area formed by the slag retaining weir around the scum scraping plate, which is scraped to the slag collecting bucket by the scum scraping scraper and discharged out of the pool.

The moving scraping suction machine is suitable for the sludge removal and scum removal of the radial flow primary sedimentation tank and secondary sedimentation tank. The center drive mud scraper is a center buttress type center drive, and the platform is fixed buttress type. It is driven by the worm gear reducer installed on the center water inlet column pipe, and driven by the internal meshing gear of the center slewing bearing to drive the frame steel structure, mud suction pipe arm, mud collecting tank, mud suction pipe road, slag skimming device and other components to rotate, usually with a diameter range of 8m to 20m.

The lower part of the small-scale mud scraper adopts the integral counter spiral scraper, the lower part of the medium and large-scale mud scraper adopts the multi plate inclined scraper, the upper scum collection device, the pool center water distribution and sludge discharge. Flat suction nozzle self suction type; the pool can be flat bottom flow or inclined bottom. The central water inlet and the surrounding drainage are adopted to ensure the uniform water flow.

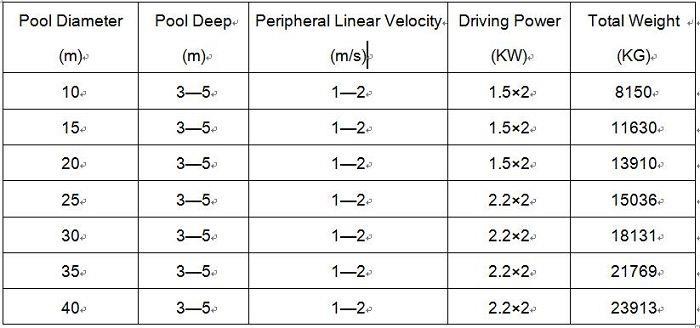

Technical parameters

Detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The mud scraper selects low-speed mechanical equipment for extrusion molding. There is no filter cloth or mud nozzle in all the equipment. The spiral action main body has its own cleaning capacity, is not blocked, and can conveniently maintain the oil content of the sludge dehydrator. Due to the filter structure which is not easy to block the screen yarn, it will clean once every 1-3 hours, once about 7 minutes. Compared with the traditional mud scraper, the center drive mud scraper can save water resources as soon as possible.

The center water inlet and peripheral drainage are selected for the mud scraper to ensure uniform water flow. The method of sludge discharge is to set up single pipe and double pipe at the bottom of the pool to absorb mud and collect it to the bottom mud collecting barrel for sludge discharge, or to select all mud scraper plates to scrape the sludge to the mud collecting pit and discharge it, or to select other methods of sludge discharge.

The scraper is also equipped with scum scraping and sweeping equipment, mechanical and electrical overload protection equipment. The center drive mud scraper can be set up with computer networking according to the user's requirements. During operation, each suction pipe is a self-contained unit, and the suction concentration can be controlled by the flow control valve in the central sludge collecting tank. The control box is outdoor type, with stainless steel shell, double-layer door seal, manual and long-distance control. The underwater part of the center drive mud scraper is made of stainless steel

Hot Tags: retrofitting traveling bridge filters, China, suppliers, manufacturers, factory, customized, price, OEM